Man I forgot how much sanding was involved. I probably could have done more too!

Wednesday, June 22, 2016

Tuesday, June 7, 2016

I will never ever scoff at the price of a wooden glass on fins at the shop.

So I'm making some Keel fins for this new eight foot fish Simmons and I'm trying to get the fins just right. I want to get a certain halo around the fans that you see often times on a wooden fin. Last night I put four layers of six ounce fiberglass cloth and it came out feeling really thin so tonight I doubled it to eight layers on the other side. I started working around 8:30 and its now 11:30. Now I know that the manufacturers that make these have ways of making them look great and I'm just a weekend warrior at this at best but it does take a lot of time to get it done remotely close to right.

Monday, June 6, 2016

I glassed the first side of the fins. It's super important to take time to shape and sand your fins. For me I need to take the time before I glass the board or else I start to get to close to the end product of a completed board and I don't give the fins the attention they should get. I was given some polyester resin at a surf show called the Board room recently. Grateful for the gift but that stuff is stinky and toxic. I prefer to work with epoxy.

Sunday, June 5, 2016

Wednesday, June 1, 2016

Friday, May 27, 2016

Rough Sanding Completed

I was super eager to make progress and made a few mistakes. The board isn't ruined, as a matter of fact these boards are so tough several mistakes can't kill them. I am going to set up a sanding light to work out some symetry issues.

Monday, May 23, 2016

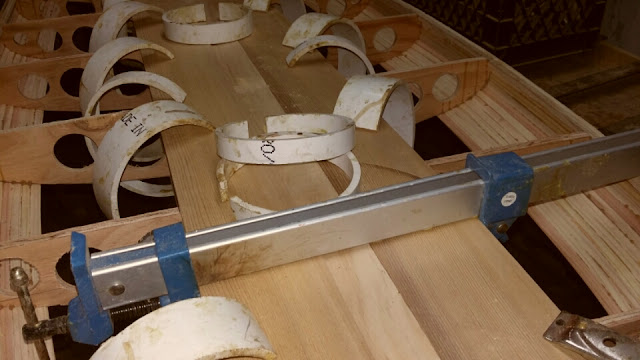

Adding Blocks To Have A Surface Clamping

I found a sure fire way to get a solid hold on gluing nose pieces to the front of a board. I glued blocks that can easily be planed and sanded off. I won't hesitate to do this again. It worked super well.

Sunday, May 22, 2016

The Texas Twin

Texas Twin Fin

I have been able to sand down much of the blocks on the nose and tail. The project sat for a while, but I'm excited to be back in the shop again!

Texas Twin Fin

I have been able to sand down much of the blocks on the nose and tail. The project sat for a while, but I'm excited to be back in the shop again!

Saturday, February 6, 2016

Moving off of the rocker table and to the stands!

The rocker table serves a function for maintaining your rocker and balance in the board so the board doesn't twist. But eventually to get those bottom planks you have to move the board to the stands. I use the bar clamps because the boards of twisted in storage so I have to bend them back into place. I really prefer each blank to be clamped to eat rib eye just makes me feel like the board is going to be a stronger board and will last longer that way. Sometimes you will have ribs separate from the deck, but that happens after the glassing process. Sometimes you can even feel it under your feet as you surf the board. But by then the board is wrapped in glass and its never going to be an issue.

Wednesday, January 27, 2016

Preparing the Frame For sanding the rails flush

Tonight I had to support the tail run off peices. I am letting the nose peices run a bit wild, but the tail needs to be strong and manageable when it comes to mounting ornamental bits.

Thursday, January 21, 2016

Rail Method: Bead n Cove

I am almost finished with building the rails on thisb 8 foot fish. It's a slow process. If I use gorilla glue, I can fit 2 to 3 gluing sessions in (morning, afternoon, night) becuase it dries just that fast. The down side is that its an expanding glue and you have to clean up sections that expand and get in the way of the next lamination. I used Tightbond Type III waterproof glue this time and found I could laminate in 12 hour repetitions. This is where I am at with one more repetition left.

Monday, January 11, 2016

Tooling and Techniques

I tend to make one more year maybe two. It feels good to be using some techn iques in the new project that continue to work for me. For each step along the way whether it milling or application it always feels second nature to me to question and wonder if there's a better way of doing things. I think this is my 12 board and several things are coming back to me that I would not change.

Whether it is working with a table saw or a router table feather boards are always very helpful especially when working with thin quarter inch thick material.

I am always grateful when I can get to my first being co strip because the frame gets incrementaly stronger with each gluing.