Tuesday, December 31, 2013

Saturday, December 28, 2013

Excited to start a new 7'10" single fin

Well christmas has come and gone looking upon New Years Eve in just a few days. Starting a new board today.

Monday, November 18, 2013

Spent a lot of time in the garage last night needed a break. I spent some time checking out what folks are willing to share about.the various ways they construct and mill their lumber for hollow wooden boards. This was an interesting way to maintain consistency in ripping lumber.

Friday, November 15, 2013

Monday, November 11, 2013

Surf Sufficient - How To Make A Canvas Surfboard Bag

http://www.youtube.com/v/31RJGX_BJDU?autohide=1&version=3&attribution_tag=6Q4ygtN6Ms0p3efmV3RF6A&autohide=1&showinfo=1&feature=share&autoplay=1

Make a simple woodworking box joint jig

http://www.youtube.com/v/bTd81dlRQiE?autohide=1&version=3&attribution_tag=x1qf1VTDiJ8WMZKQ-nGA-g&autoplay=1&showinfo=1&feature=share&autohide=1

Wednesday, September 25, 2013

Fun Fat Bouyant Boards, 7'4" Single Fin Double Concave...

Wednesday, July 10, 2013

Tuesday, June 11, 2013

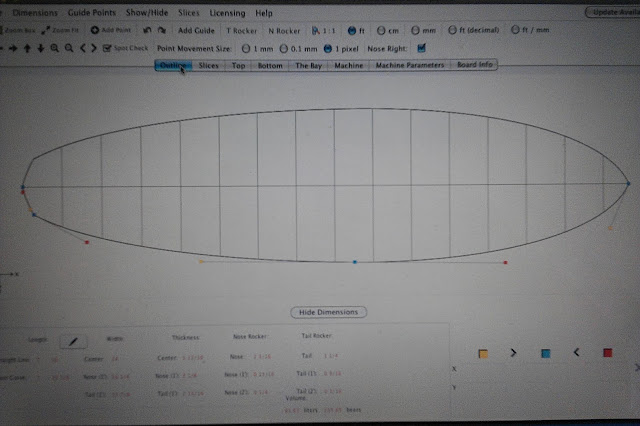

8 Foot Fish Design Akushaper

Monday, May 27, 2013

Wednesday, May 8, 2013

Gloss coat issues....potatoe chips...

I have had resin act this way once before. In certain areas the resin repels. I attributed this to a previous board I was in a hurry to glass and I used just any old rah on the garage to wipe it down before applying glass. It was super disappointing to see but I had to sand it down and repoor. This occurrence isn't as bad and o can probably just sand it down then polish it, we were macking some chips after sanding for several hours. We wiped down the board with a wet rag, bit as you know oil and water do not mix. So I am jumping to the conclusion that we need to cit our cholesterol intake while prepping a board for hot and gloss coats.

Put A Cork In It!

Sunday, May 5, 2013

Sanded Hollow Wooden Surfboard...

Wednesday, April 24, 2013

7'0" Completed

Really looking forward to giving it a shot in the water soon!

Tuesday, April 23, 2013

New 9'4" In The Design Process No Name For It Yet...

Most all of the boards I design revolve around two motivations.

- How I want the board to behave in a particular setting.

- Or a new construction technique.

This next board is designed with a few things I want to try...

- I want a board that is easy to carry under my arm.

- Single fin (already got that fin designed will post pic later).

- I want it to be responsive, but long enough to paddle easily.

- Buoyancy is always good.

- A rocker that works in smaller waves (less rocker).

- Want to maker it lighter so I'm using 1/8th inch ribs. I'll need to reinforce it with 1/4x1/4 inch cedar pieces on each rib.

- I also put the ribs at 6 inch on center in the middle and 8 inch on center towards nose and tail. That's why the distances between slices may seem larger at nose and tail.

After two really good sessions this weekend...

So after a great weekend of surfing and thinking about what board size does for us in the water I've come to a new concept.- Carrying a board under your arm is nice, but there's nothing quite like speeding along a line up because you're not worried about falling down.

- So I've widened the 9'4" to 23.75

- For us shorter more stocky fellas, buoyancy and width in a board is important for paddling and catching waves.

We spend so much time working on these boards that it's very important to design them well before hand.Feel free to check on your opinion of these new dimensions I drew up last night.

Sunday, April 21, 2013

7'0" Single Fin Hot Coat

Thursday, April 18, 2013

Monday, April 15, 2013

Bottom Hot Coat Complete

Fin Glassing

Maybe you've heard the old saying it's going to get worse before it gets better. That's exactly what you can expect when laminating a fin onto a surfboard. In building a surfboard you spend a lot of time refining the shape and the surface. Making a mess while laminating the fin is the last thing on your mind.

Fins plug and air vent installed...

Leash and Vent Holes

This is a pretty exciting part of board building. You've already...

- Designed the board with Akushaper

- Cut the skeleton

- Milled the bead and cove rails (which you can see in the tail portion in this photo)

- Built the rocker table

- Made your top and bottom decks

- Glued it all down to the skeleton

- Shaped/Sanded the board into shape

- Laminated the 6 oz cloth top (2 layers and bottom 1 layer)

- Glassed on the fin(s)